Zinc Oxide Dross 25Kg Pack

Short Descriptions

Zinc Oxide is considered as Hazardous Material

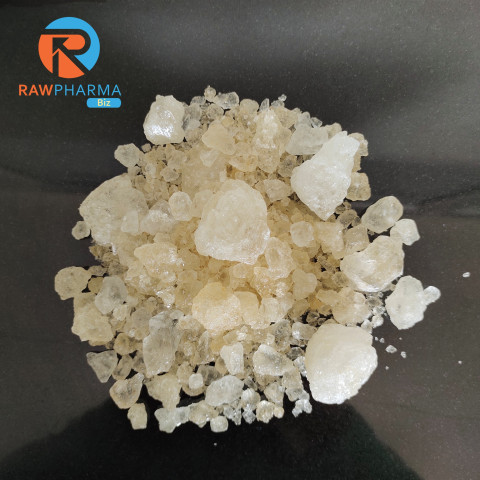

Zinc oxide dross is a byproduct of the galvanizing process, composed primarily of zinc oxide along with small amounts of other metals and impurities. It appears as a powdery, granular material and is often generated when molten zinc reacts with oxygen during the coating of steel. This dross is typically recycled to recover zinc and other valuable metals, making it an important material in the zinc recycling industry. It plays a crucial role in reducing waste and promoting sustainable practices in metal manufacturing and processing.

More Information

Details

Zinc oxide dross is a byproduct formed during the galvanizing process, where molten zinc reacts with oxygen, resulting in a powdery, granular material composed primarily of zinc oxide along with traces of other metals and impurities. This material is generated when steel is coated with molten zinc to prevent corrosion, an essential step in producing galvanized steel.

The primary use of zinc oxide dross is in the recycling industry. It is processed to recover valuable zinc and other metals, which can then be reused in various applications. The recovered zinc is often employed in the production of new galvanized steel, brass, and other zinc-containing products, ensuring that the material is efficiently repurposed and not wasted.

Recycling zinc oxide dross plays a significant role in promoting sustainability within the metal manufacturing industry. By recovering and reusing the zinc, the industry can reduce waste and conserve natural resources. This process not only supports environmentally responsible practices but also helps in maintaining the economic viability of the galvanizing industry by maximizing the utility of all materials involved.